In the rapidly evolving global manufacturing landscape, the quest for innovation, efficiency, and market access has led to the emergence of manufacturing co-investment hubs. These hubs represent a paradigm shift, blending shared investment with collaborative operations to address the sector’s most pressing challenges.

This comprehensive article explores the concept, benefits, challenges, and future potential of manufacturing co-investment hubs. It positions these hubs as transformative engines of growth and innovation, reshaping how manufacturers invest, produce, and compete in an interconnected world.

Understanding Manufacturing Co-Investment Hubs

A manufacturing co-investment hub is a centralized facility or network where multiple entities—such as manufacturers, governments, private investors, and technology providers—collaborate by pooling resources and capital. These hubs serve as shared ecosystems designed to optimize production capabilities, foster innovation, and promote industrial growth.

Key Features of Manufacturing Co-Investment Hubs:

- Shared Infrastructure: Advanced facilities and technologies accessible to all stakeholders.

- Collaborative Investment: Joint funding by partners to reduce individual capital risks.

- Knowledge Exchange: Cross-industry collaboration fostering innovation and efficiency.

- Sustainability Focus: Emphasis on energy-efficient processes and circular manufacturing.

Why Manufacturing Co-Investment Hubs Are Transformative

The manufacturing industry faces several challenges, including high capital costs, technological disruptions, and global supply chain complexities. Co-investment hubs address these issues by:

1. Reducing Financial Barriers

Manufacturers often struggle with the significant capital required for advanced facilities or cutting-edge technology. By pooling investments, hubs lower the financial burden on individual companies, making innovation accessible to small and medium enterprises (SMEs).

Example: A co-investment hub specializing in semiconductor production shares the cost of cleanroom facilities among multiple companies.

2. Driving Innovation

Co-investment hubs act as innovation accelerators, enabling participants to leverage shared R&D resources and expertise. Collaborative environments foster breakthroughs in materials science, automation, and production techniques.

Insight: Co-investment hubs often include partnerships with universities and research institutions, bridging the gap between academic innovation and industrial application.

3. Enhancing Scalability

Hubs allow manufacturers to scale production without the need for full ownership of facilities. This is particularly beneficial for startups and SMEs looking to expand without overextending resources.

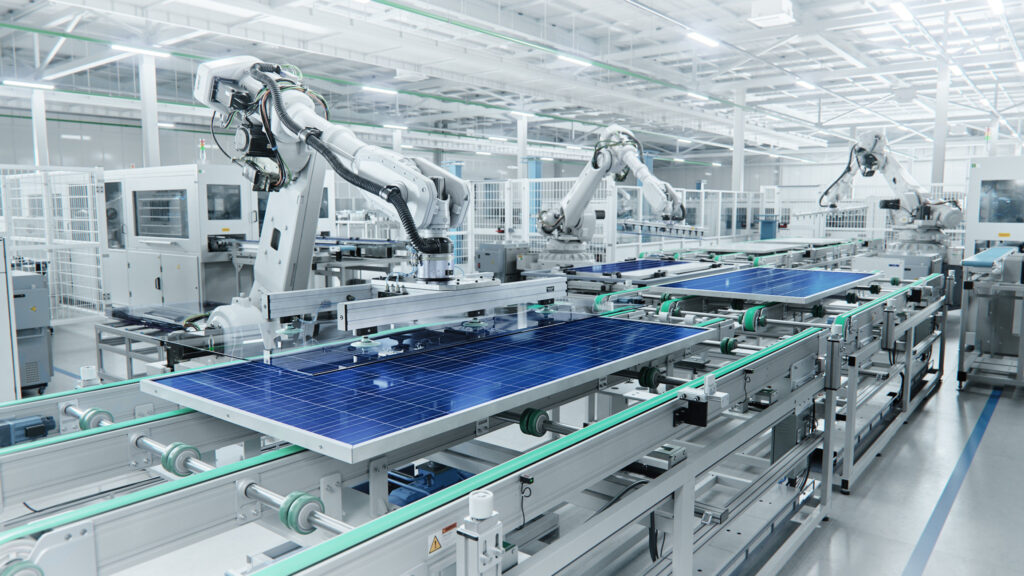

Case Study: A green energy startup uses a co-investment hub to prototype solar panel designs, avoiding the need for standalone infrastructure.

4. Promoting Regional Growth

By establishing hubs in strategic locations, governments and industries can stimulate regional development, creating jobs and boosting local economies.

Example: A co-investment hub in a developing country attracts foreign manufacturers while upskilling the local workforce.

5. Strengthening Supply Chains

Hubs create integrated supply chain networks by co-locating manufacturers, suppliers, and logistics providers, reducing transportation costs and time-to-market.

Types of Manufacturing Co-Investment Hubs

1. Sector-Specific Hubs

Focused on a particular industry, these hubs support specialized manufacturing processes.

- Example: Aerospace hubs providing advanced composite material facilities for aircraft production.

2. Technology-Centric Hubs

These hubs revolve around cutting-edge technologies such as robotics, AI, or additive manufacturing.

- Example: 3D printing hubs offering shared access to high-end printers for prototyping and production.

3. Regional Development Hubs

Designed to promote industrial growth in underdeveloped areas, these hubs often receive government backing.

- Example: Textile manufacturing hubs in Africa aimed at revitalizing the local garment industry.

4. Sustainability-Focused Hubs

Centers dedicated to eco-friendly manufacturing practices, including renewable energy integration and waste recycling.

- Example: A hub that recycles industrial waste into raw materials for construction.

Benefits of Co-Investment Hubs

1. Risk Mitigation

By spreading costs and responsibilities among multiple stakeholders, hubs reduce the financial risks associated with large-scale manufacturing projects.

2. Knowledge and Technology Transfer

Collaboration among diverse participants fosters the exchange of ideas, accelerating innovation.

Example: An automotive manufacturer learns advanced automation techniques from a robotics company within the hub.

3. Resource Optimization

Shared facilities and equipment eliminate redundancies, optimizing resource utilization.

4. Market Access

Companies in co-investment hubs gain exposure to global markets and partnerships, boosting competitiveness.

Case Study: A co-investment hub in India connects manufacturers to export markets in Europe and the Middle East.

Challenges of Co-Investment Hubs

1. Governance Complexities

Managing diverse stakeholders with varying goals and priorities can lead to conflicts.

- Solution: Establish clear governance structures and decision-making frameworks.

2. Intellectual Property (IP) Concerns

Collaboration increases the risk of IP theft or misuse.

- Solution: Implement robust IP protection agreements and technology-sharing protocols.

3. Initial Capital Requirements

Setting up a hub requires significant upfront investment, which may deter participation.

- Solution: Seek government incentives and private-public partnerships to fund infrastructure development.

4. Scalability Challenges

Balancing growth with resource availability and infrastructure capacity can be difficult.

- Solution: Plan modular expansions to accommodate future growth.

Real-World Examples of Co-Investment Hubs

1. GlobalFoundries Technology Hub (Singapore)

A semiconductor manufacturing hub that pools investments from multiple stakeholders to drive innovation in chip production.

2. Advanced Manufacturing Research Centre (UK)

A collaboration between the University of Sheffield, Boeing, and other partners, this hub focuses on R&D for aerospace and automotive industries.

3. Dubai Industrial City (UAE)

A hub designed to attract manufacturers in sectors such as food processing, logistics, and machinery, offering shared infrastructure and tax incentives.

The Future of Manufacturing Co-Investment Hubs

1. Digital Integration

Future hubs will leverage digital twins, IoT, and AI to optimize processes and enable real-time decision-making.

Example: A smart hub where manufacturers remotely monitor and adjust production lines.

2. Focus on Sustainability

Sustainable hubs will integrate renewable energy, green technologies, and circular manufacturing to meet global climate goals.

3. Global Connectivity

Hubs will evolve into interconnected networks, allowing seamless collaboration across countries and continents.

Insight: Blockchain technology may be used to enhance transparency in global co-investment hub operations.

4. Customized Manufacturing Ecosystems

Hubs will tailor facilities to specific needs, such as small-batch production or rapid prototyping.

Conclusion

Manufacturing co-investment hubs represent a groundbreaking model for industrial growth, combining shared investment with collaborative innovation. These hubs are not only vital for reducing costs and enhancing efficiency but also for fostering sustainable practices, driving regional development, and enabling technological advancements.

By embracing the co-investment hub model, manufacturers can navigate the complexities of modern industry while positioning themselves for long-term success. As the future of manufacturing unfolds, these hubs will undoubtedly play a central role in shaping a more collaborative, sustainable, and innovative industrial ecosystem.