Introduction: The New Age of Smart Manufacturing

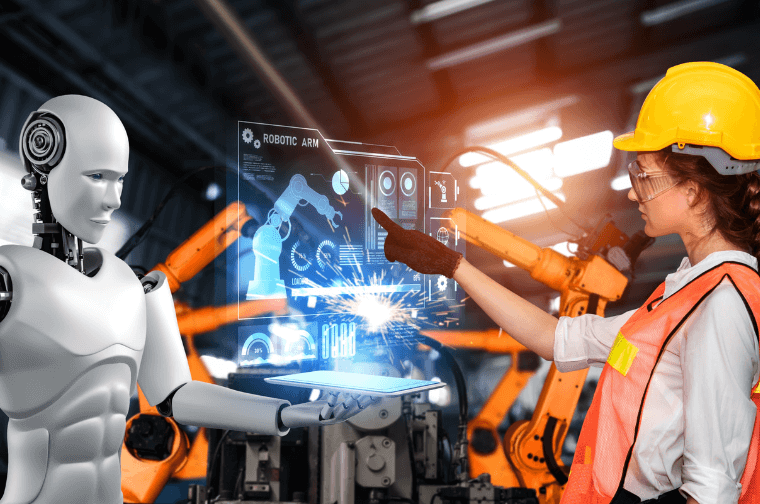

The manufacturing industry stands at the forefront of transformation. The advent of Artificial Intelligence (AI) and Machine Learning (ML) is revolutionizing how factories operate, optimize, and grow. Once considered the domain of science fiction, AI and ML have now become essential tools in creating agile, efficient, and scalable manufacturing ecosystems.

From predictive maintenance to automated quality control and smart supply chains, these technologies are empowering manufacturers to reduce costs, boost productivity, and deliver better products faster. This article delves into the depths of how AI and ML are reshaping the manufacturing sector, presenting a vision of the factory of the future—one that leverages data, intelligence, and automation to achieve unprecedented efficiency.

The Foundations: Understanding AI and Machine Learning

Before diving into their applications, it’s crucial to understand what AI and ML entail:

Artificial Intelligence (AI): The simulation of human intelligence in machines, enabling them to think, learn, and problem-solve.

Machine Learning (ML): A subset of AI, where algorithms learn from historical data to make predictions or decisions without being explicitly programmed.

AI and ML leverage vast amounts of data collected from various sources, such as IoT sensors, cameras, and enterprise systems, to analyze patterns, identify anomalies, and optimize processes in real-time. The combination of these technologies is driving a new era of smart manufacturing, characterized by self-optimizing production lines, predictive analytics, and automated decision-making.

Key Applications of AI and Machine Learning in Manufacturing

AI and ML are transforming every facet of manufacturing. Let’s explore the most impactful areas:

1. Predictive Maintenance: Reducing Downtime and Costs

Predictive maintenance is one of the most significant breakthroughs brought about by AI. Traditional maintenance schedules are often based on fixed intervals, leading to unnecessary downtime or unexpected failures. AI-powered systems, however, use ML algorithms to predict when machinery is likely to fail, allowing for maintenance to be scheduled proactively.

Benefits:

Reduced downtime by up to 50%.

Lower maintenance costs by predicting failures before they happen.

Extended equipment lifespan through optimized maintenance schedules.

Case Study: General Electric implemented AI-powered predictive maintenance for their jet engines, reducing unscheduled downtime by 25% and saving millions in operational costs.

2. Quality Control: Enhancing Product Consistency and Reducing Defects

AI and ML are revolutionizing quality assurance by automating the inspection process. Traditional quality checks are labor-intensive and prone to human error. By leveraging computer vision and deep learning algorithms, manufacturers can detect defects with unparalleled accuracy and speed.

Benefits:

Higher accuracy in defect detection compared to human inspectors.

Real-time adjustments to production processes to minimize waste.

Reduced scrap rates and improved product quality.

Case Study: Siemens uses AI to inspect their printed circuit boards, achieving a 99.7% defect detection rate, far surpassing human capabilities.

3. Supply Chain Optimization: From Raw Materials to Finished Goods

AI and ML are transforming the supply chain, making it more resilient and efficient. By analyzing data from various sources—like market trends, weather forecasts, and customer demand—AI can predict supply chain disruptions, optimize inventory levels, and reduce lead times.

Benefits:

Reduced inventory carrying costs by 20-30%.

Faster response to market demand fluctuations.

Improved supplier performance through predictive analytics.

Case Study: Unilever uses AI-driven demand forecasting to reduce inventory levels by 10% while maintaining high service levels, leading to significant cost savings.

4. Robotic Process Automation (RPA): Streamlining Operations

AI-driven robots and cobots (collaborative robots) are taking over repetitive, high-precision tasks on the factory floor, allowing human workers to focus on higher-value activities. Unlike traditional automation, AI-powered robots can adapt to changes in real-time, making them ideal for dynamic manufacturing environments.

Benefits:

Improved production speed and reduced error rates.

Enhanced worker safety by handling dangerous tasks.

Flexibility in low-volume, high-mix production environments.

Case Study: Tesla uses AI-driven robots extensively to assemble vehicles, resulting in faster production cycles and reduced human intervention.

5. Digital Twins: Real-Time Simulation and Optimization

A Digital Twin is a virtual replica of a physical asset, process, or system that can be analyzed and optimized using real-time data. By integrating AI and ML, manufacturers can simulate scenarios, predict system performance, and optimize operations without disrupting actual production.

Benefits:

Continuous optimization of production processes.

Reduced time to market through virtual prototyping.

Enhanced risk management by simulating failures before they occur.

Case Study: Boeing leverages Digital Twins to monitor the performance of their aircraft, reducing maintenance costs and improving safety.

The Benefits of AI and Machine Learning in Manufacturing

The impact of AI and ML extends beyond individual applications. Here’s how they are fundamentally transforming manufacturing:

Increased Productivity: By automating repetitive tasks and optimizing production schedules, AI boosts overall productivity.

Cost Reduction: Predictive analytics minimize waste, reduce energy consumption, and lower operating costs.

Better Decision-Making: Real-time data analytics provide actionable insights, enabling data-driven decision-making.

Scalability and Flexibility: AI allows manufacturers to scale operations rapidly and adapt to changing market demands.

Sustainability: AI optimizes energy usage and reduces waste, aligning with global sustainability goals.

Challenges in Implementing AI and ML in Manufacturing

While the benefits are compelling, implementing AI and ML in manufacturing comes with challenges:

Data Privacy and Security: Manufacturing firms must protect sensitive data from breaches.

High Initial Investment: Implementing AI systems requires significant upfront costs, though the ROI can be substantial.

Skill Gaps: The workforce needs to be upskilled to handle new technologies effectively.

Resistance to Change: Traditional manufacturers may be reluctant to adopt AI, fearing disruption.

Overcoming these challenges involves investing in training, prioritizing cybersecurity, and adopting a phased approach to AI implementation.

Future Trends: The Road Ahead for AI in Manufacturing

The future of manufacturing is intertwined with advancements in AI and ML. Here are the top trends to watch:

Edge AI: Using AI at the edge (i.e., at the source of data collection) will enable faster decision-making, especially in time-sensitive applications.

AI-Driven Autonomous Factories: Fully automated factories that operate with minimal human intervention are on the horizon.

Sustainability and Green AI: AI will play a critical role in achieving zero-waste manufacturing and reducing carbon footprints.

AI-Powered Cybersecurity: Protecting interconnected systems from cyber threats will become a top priority as factories become more digitized.

Conclusion: The AI-Driven Future of Manufacturing

Artificial Intelligence and Machine Learning are not just enhancing manufacturing processes—they are redefining the industry. From predictive maintenance to automated quality control and supply chain optimization, AI’s impact is profound and far-reaching. As manufacturers continue to embrace these technologies, the industry is set to achieve unprecedented levels of efficiency, innovation, and sustainability.

For businesses looking to stay competitive, now is the time to invest in AI and ML capabilities. Those who fail to adapt risk falling behind as the industry marches forward into a new era of intelligent manufacturing.

Frequently Asked Questions (FAQs)

How can small and medium-sized manufacturers adopt AI?

Start with small pilot projects focusing on areas like predictive maintenance or quality control, then scale up as ROI becomes evident.

What is the difference between AI and ML in manufacturing?

AI focuses on automating decision-making processes, while ML is about using data to learn and improve predictions over time.

What are the most common AI tools used in manufacturing?

Popular tools include TensorFlow, PyTorch, and cloud-based platforms like AWS Machine Learning and Microsoft Azure AI.